Jewelry Making: From Wax to Wow

Introduction: More Than Just Jewelry

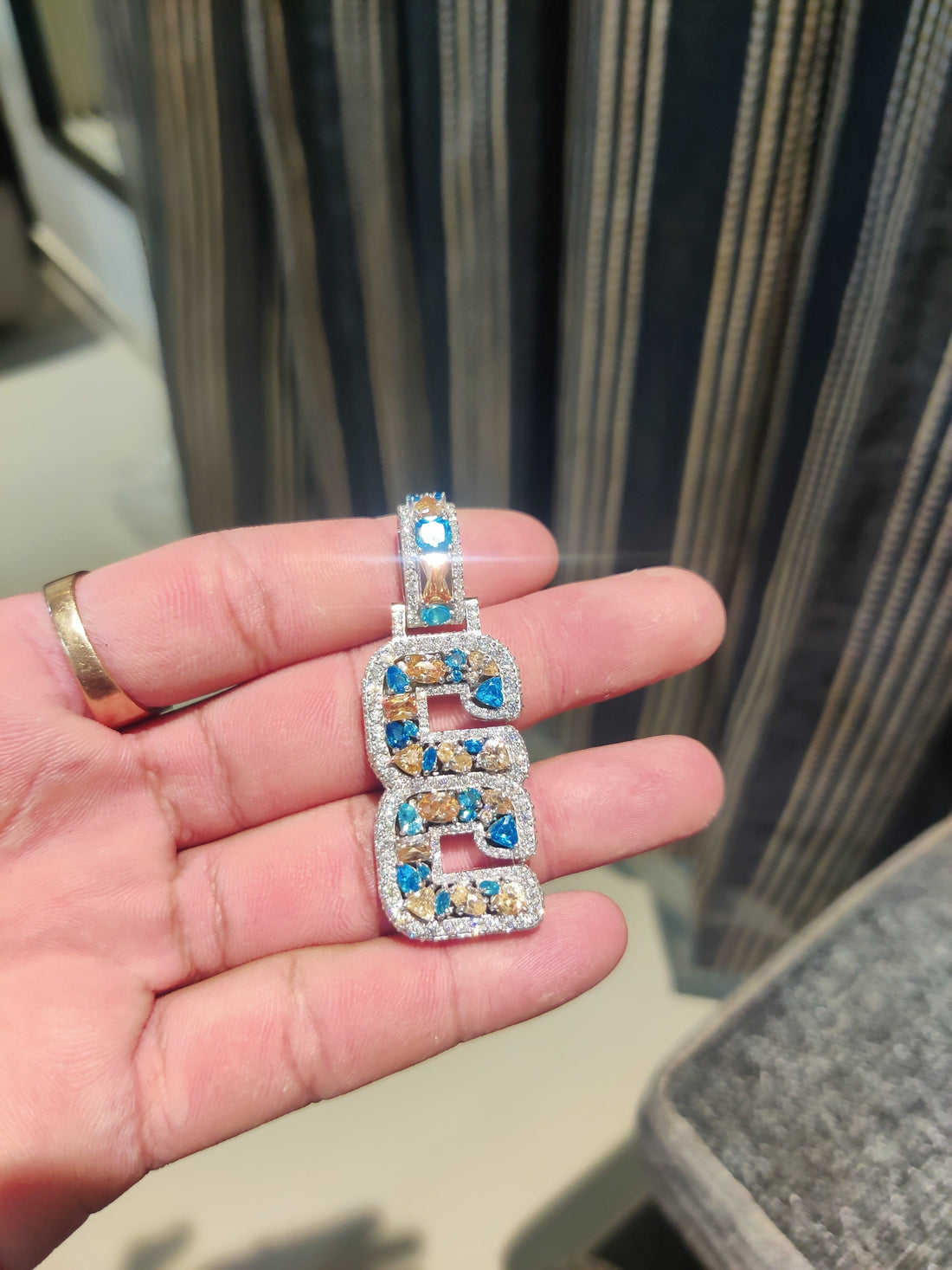

Each pendant has a backstory. It is not only about the shiny gloss or the sparkling diamonds; it is about the artistry, creativity, and passion that go into creating wearable art. Before reaching your skin, every piece at Gemglow Jewels, especially our statement Pendant goes through a rigorous process. What you wear is a gold-sculpted story, not just jewelry.

Inspiration for Design: The Starting Point

A creative spark starts the adventure. A rough sketch, a name, or an abstract concept are frequently the first steps in our design process. The bold, stylized letter "B" which stands for edge and identity, served as the idea for this statement pendant.

We take into account:

- The piece's purpose or backstory

- Target personality = brash, outspoken, and distinctive

- Gemstone color schemes that complement the message and mood

From this, we develop a vision as well as a design.

CAD Designing: Precision in Every Pixel

After the concept is complete, Computer-Aided Design (CAD) software is used to bring it into the digital realm. CAD guarantees precise stone placements, symmetry, and dimensions.

Important CAD components:

- Ideal prong positioning for the security of the gem

- balanced stone arrangement with champagne and blue hues

- Developing the pendant's balance and weight

In this stage, mathematics and art come together to create a blueprint that is just as stunning as the finished product.

Wax Model: Forming the Initial Shape

The wax prototype is the next stage, which is essential to seeing the pendant in real life. The CAD design is converted into a wax mold that replicates every minute detail, from the tiniest claw to the chain loop, using high-resolution 3D printers.

This helps us:

- Verify the measurements and scale.

- Find any defects or weaknesses in the design.

- Verify the stone fitting spaces.

Before deciding on precious metals, designers and clients can get a tactile impression with the wax model.

Casting: Bringing the Pendant to Life

It is time to cast the piece in metal, in this case fine white gold, when the wax model is perfect. The most common technique is lost-wax casting, in which molten metal is utilized in place of the wax mold after it has been melted away and covered with plaster.

Actions taken:

- Investment: Encasing the wax in plaster

- Burnout: When wax melts, a hollow mold is left behind.

- Pouring: Putting molten gold or silver into the mold.

The outcome? An unpolished yet intricate metal rendition of your striking jewelry.

Stone Setting: The Sparkle of Personality

After casting, talented craftspeople start the stone setting procedure, which gives the pendant its vivid vitality. Our design incorporates a striking combination of blue heart-shaped jewels and champagne.

Setting specifics:

- Custom-cut grooves are necessary for heart-shaped stones.

- Maximum brilliance is ensured by high-precision pave craftsmanship.

- For precision, stones are manually placed under magnification.

At this point, the work begins to really shine, both emotionally and literally.

Polishing & Finishing: The Final Touch

After setting, the pendant undergoes multiple rounds of polishing, plating, and quality checks. This final stage ensures every edge is smooth, every surface reflective, and every stone secure.

The pendant goes through several polishing, plating, and quality control steps after it has set. This last step guarantees that every stone is secure, every surface is reflective, and every edge is polished.

Final ending consists of:

- Using rotary tools for extremely fine polishing

- Rhodium plating is optional for added brightness.

- Last check to guarantee longevity and brightness

The outcome is a completed pendant that exudes luxury, skill, and passion.

Conclusion, more than just an accessory

What started as a sketch evolved into a wax figure, a digital blueprint, and ultimately a glowing pendant. The process of making a statement pendant combines engineering and art, craftsmanship and technology, and accuracy and vision.

Wearing it is more than just wearing jewelry; it is a bold, gold-cast personality, a dream, and a story.

FAQs

-

It typically takes 10 to 21 days, depending on the design complexity, materials, and stone setting.

-

We use premium materials like sterling silver, white/yellow/rose gold, and high-quality gemstones like moissanite, CZ, or lab-grown diamonds.

-

Yes! At Gem Glow Jewels, you can fully customize your pendant, from the shape and font to the stones, color, and size.

-

Yes, every pendant is hand-assembled and stone-set by expert artisans, ensuring quality and attention to detail.

-

Absolutely. Every gem is hand-set using secure prong or bezel techniques so they stay in place, built for style and durability.

-

Yes, we ship worldwide. Shipping times and customs fees vary based on your location.

-

Definitely. Our designs are bold and expressive, perfect for anyone who wants to stand out, regardless of gender.